PlateWeld Slab

The technique of CO2 welders operates at a short wavelength that is less absorbed by metals. This increases efficiency in metalworking and results in a "smooth weld." Adjusting the wavelength and power is more flexible in a CO2 laser compared to a Fiber laser.

A CO2 laser, how does that work in detail?

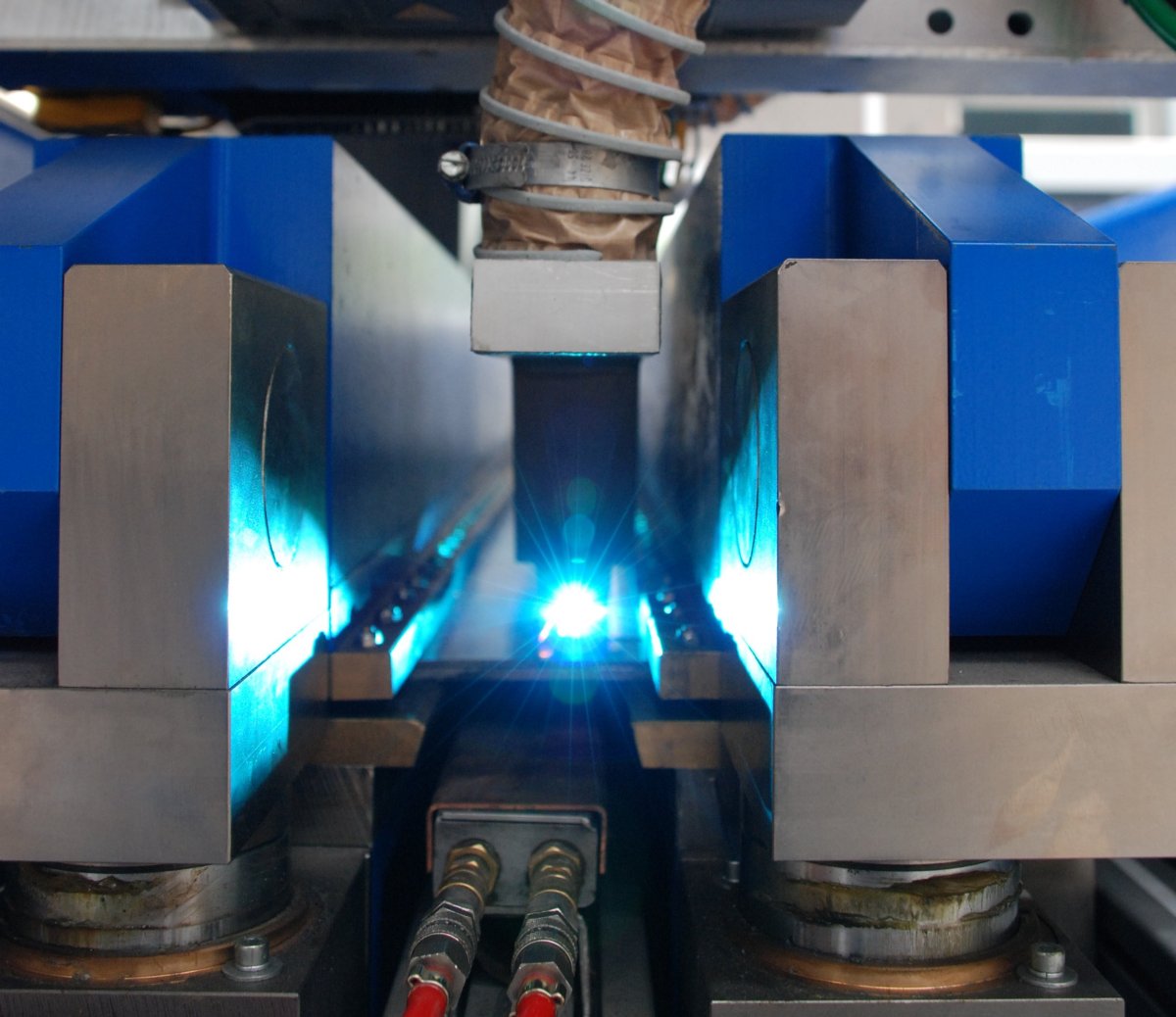

A CO2 laser generates an intense laser beam by stimulating carbon dioxide molecules through electric discharge. This discharge occurs between electrodes in a gas-filled tube. The stimulated CO2 molecules emit photons, resulting in the creation of the laser beam, which typically has a specific short wavelength. The laser beam is focused using a nozzle to create a concentrated energy source. This concentrated laser beam is directed onto the material to be processed, heating and melting the surface layer. In welding, two materials are joined as the melted areas fuse together and then cool.

The major features of our Plateweld Slab are:

- CO2 lasers exhibit high energy efficiency and made a smooth weld

- The focus and intensity of the CO2 laser beam can be precisely adjusted, enabling fine welding

- The shorter wavelength of the CO2 laser results in less heat deflection

- Due to the low wavelength, the welding station does not need to be completely enclosed

- Able to weld combi of 0.6mm on 2.5mm

- The shorter wavelength ensures that the process does not take place in a closed compartment.

- Water cooled clamping bars to prevent protection foil from melting

- Decades of experience, resulting in maintenance and operator friendly design

- Offering preventive maintenance, breakdown support and spare parts supply

The PlateWeld Slab system consists of two infeed- and two outfeed tables, a enclosed laser cabinet with a safety lock door and dome cameras to view the welding process. Two rigid clamping bars transport the plates in short indexing steps through the laser welding cabinet. Two other rigid clamping bars press the materials together during welding. Shielding gas is preventing oxidation of the top and bottom plate. The laser head creates the welding shapes, controlled by the welding program from the PlateCam - CAD Software.