Laser Welding of Stainless Steel Panels

Laser welding is already for over 30 years a competitive alternative for traditional spot- and seam welding. First by using the CO2 laser, but especially after the introduction of the Fiber laser, laser welding has grown to the new standard in welding applications.

The advantages of laser welding versus traditional spot- and seam welding are many, like:

- Faster production with less material.

- Very strong, reliable, constant high-quality welds.

- Convenient for the welding of stainless steel, carbon steel, duplex, titanium and numerous other alloys.

- Less deformation during welding, because of relatively low heat-input by the laser beam.

- The inside of the tank is not affected. No rework needed, even the protective film can stay on during welding.

- Unlimited under-plate thickness, as the laser beam only penetrates from one side.

- As any shape can be designed and welded, tailored solutions can be created.

- Fully automated welding-process with low cost of labour and high-quality end product.

Laser welding is gaining popularity in the production of stainless steel pillow plates. Pillow plates, also named dimple plates, are used for isolated tanks and heat exchangers in many different industries.

Pillow plates / dimple plates

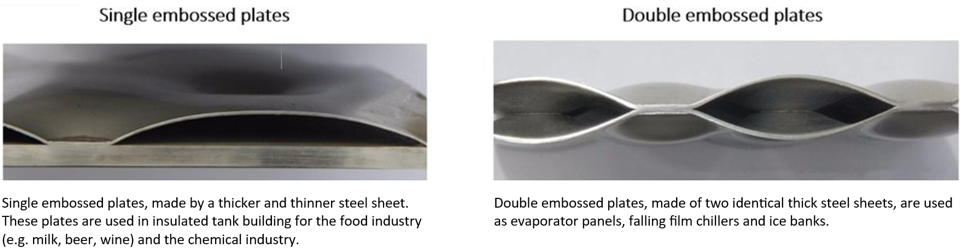

A pillow plate, or dimple plate, is a construction of two spaced thin stainless-steel sheets, laser welded to each other. The wavy ‘pillow shaped’ surface is created by pressurized inflation and allows cooling (or heating) fluids to circulate. The pillow plate has a high heat transfer coefficient and shows less chance of leaking due to the consistent quality of laser welding.

There are two types of pillow plates, with each their own usage:

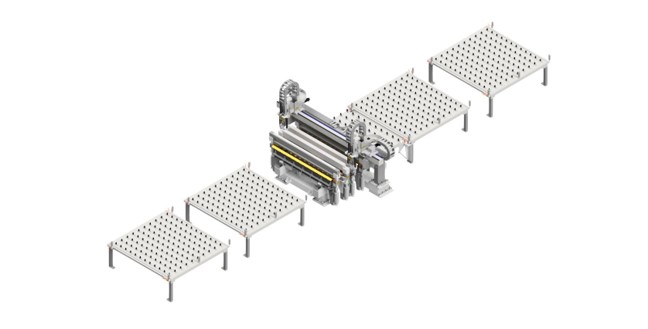

Zenna Laser Solutions launched the first PlateWeld installation for the production of laser welded pillow plates in 1990. Over three decades Zenna became the worldwide market leader in building dimple plate laser welding systems.

Advantages of Zenna's decades of experience combined in the PlateWeld

- Rigid clamping of the plates is of utmost importance for a good weld.

- Cooling is most essential to prevent protection foil from melting and limit plate deformation.

- Axial positioning system allows fast and accurate movements of the laser head.

- Good housing guarantees the safety of the operator.

- Superior PlateCam software makes the difference in productivity, welding possibilities and competiveness.

- Break down and maintenance support by experienced technicians.