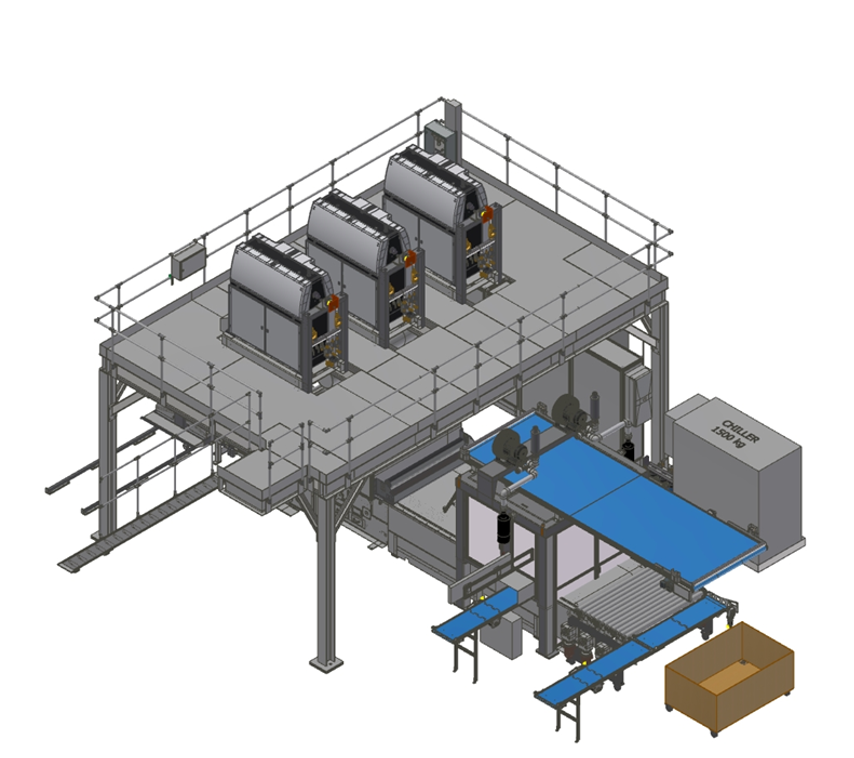

MultiCutter Combi

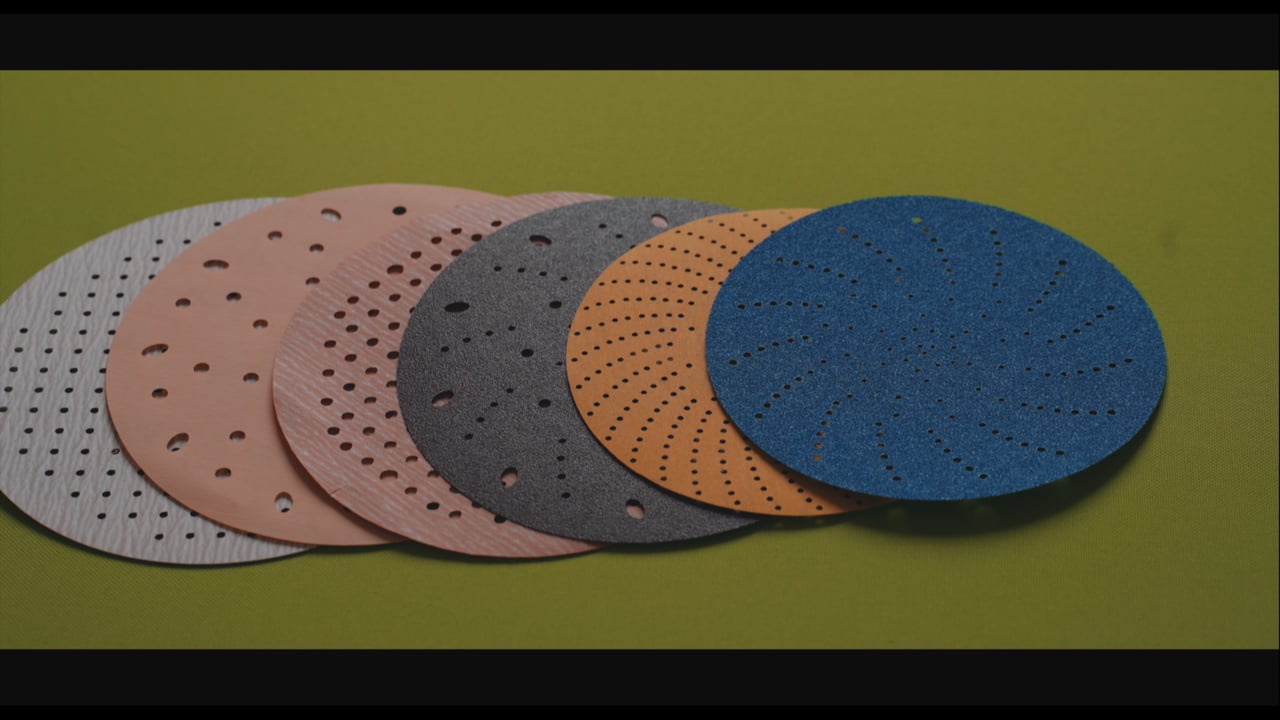

MultiCutter Combi, our recently introduced wide web laser solutions, is specially designed to convert fiber as well as sandpaper material. This unique laser line is able to cut the most coarse fiber and also any shape sandpaper with any hole pattern, including multi-hole discs and sheets.

The MultiCutter Combi can cut 'disc-to-disc'. There is no trim in between the fiber discs, improving the material yield significantly up to 10%, lowering waste volume and disposal cost.

The combination of proven technology and new innovations make the MultiCutter Combi a powerful production tool for the abrasives industry. Many companies experience the business potentials and benefits of using Zenna’s laser cutting machines, confident by the good support and service.