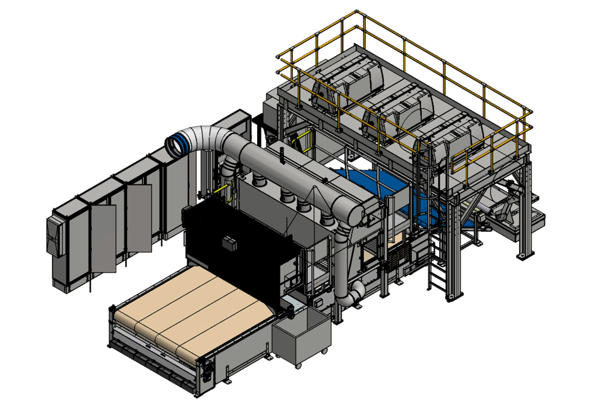

Falcon FF 20/2600 (single layer)

The ZennaLaser Falcon FF 20/2600 is a very fast and accurate laser line for cutting single layer Flat Fabric. The Falcon FF is equiped with three high power lasers that cut continuously on proceeding fabric with a minimum of free space between every nesting repeat. The scanners are static positioned and have a special Zenna designed Protection windows against smoke and debris contamination, leading to substantial less cleaning time.

Roll changes progress automatically with the new Feed-in module, as is the waste separation. Picking the parts from the STM-belt into boxes requires only a few workers. Labor requirement is therefor significantly lower than MultiLayer lines, where paper and foil separation bring extra labor intense production steps.

The Falcon FF has a compact design, using only 25% of the floor space of a conventional multilayer laser line, while producing the same or even more output. The optional second platform for chiller/cabinets will even further limit required floor space.

The Falcon FF 20/2600 is the most agile and flexible high-tech cutting tool in the market.

Different fabric or material width?

Zenna Laser Solutions is specialised in making client specific laser cutting lines. According to your material and requirements, Zenna has fabric cutting solutions for narrow web up to 500mm, wide web up to 1.500mm and XL wide web up to 4.000mm. These cutting lines can be equiped with one, two, up to 6 lasers, Vision technology for inspection and robots for product handling.

Interested? Please contact us for more information and tell us your specific wishes.