BannerMarker 50/300

The ZennaLaser BannerMarker is a well designed compact laser marking system, suitable for intensive and continuous marking of logos, arrows, or text on insulation wool with a maximum width of 300mm. The Banner-Maker operates on the same technology as the FlexMarker but has a smaller width range, making it a economical investment. The BannerMarker can be integrated easily into an existing production line, due to its compact setup. The system is ideal for marking outline or filled characters, resembling a printed banner on continuously moving wool. Changes in arrows or text can be made "on the fly," either remotely by a central control system or locally at the laser using a touch screen. Different thicknesses of the wool are compensated for by the digitally adjustable focal distance.

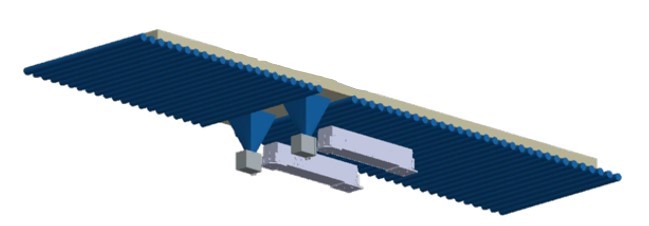

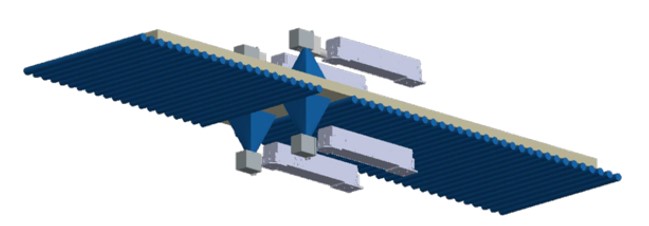

The laser marking system is built on a bridge-type frame, mounted over the production line and requires only 3 meters free length. The laser and scanner are mounted facing down to the wool. The electrical cabinet and chiller can be placed on top of the frame or next to the line. The complete laser installation is housed in a ventilated cabinet in order to stay dust free and uses a minimum of space in the production line.

Most clients prefer the BannerMarker Duo installation with two lasers enabling to mark two panels/blocks parallel. The flex-positioning option allows the banner position to move across the material (fully automated).

Laser marking with a Banner-Marker is gaining popularity with the insulation wool producers, as the advantages versus “hot wheel”, press, and ink-jet marking are significant:

- High reliability, no moving parts and nozzles in a dusty environment

- Time stamp or batch code for traceability and anti-counterfeiting

- Changeovers in less than a second without stopping

- Instant switching between active marking and standby

- The flexibility to switch to the patern or logo you want in a split second

- No heating-up delays and costly idle time

- The ideal system for fast and highly accurate marking up to a maximum width of 300mm