Laser Marking Insulation Wool

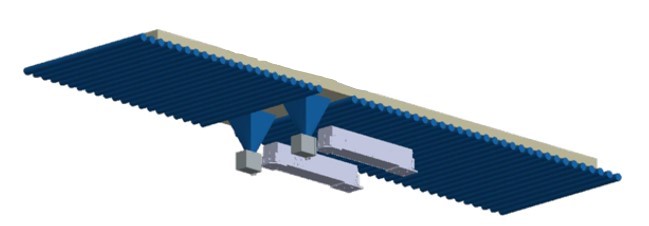

Do you recognize a wish to increase product awareness and branding? There is a worldwide growing interest in branding mineral wool panels with firm logos, grids, and R-values. Laser marking is the solution!

Laser Marking, also often referred to as laser engraving or etching, is a technique to make a permanent mark on materials. The marks are often product names, logos, grids, batch numbers, or arrows. It is a contact-free process that offers high-quality visual results on an extensive range of materials, such as (coated) metals, plastics, and natural materials.

Laser marking is gaining popularity with the insulation wool producers, as the advantages versus “hot wheel”, press, and ink-jet marking are significant:

- High reliability, no moving parts and nozzles in a dusty environment

- Time stamp or batch code for traceability and anti-counterfeiting

- Changeovers in less than a second without stopping

- Instant switching between active marking and standby

- No heating-up delays and costly idle time

- Logo drawings and designs are stored in a local database and can be activated by centralized control