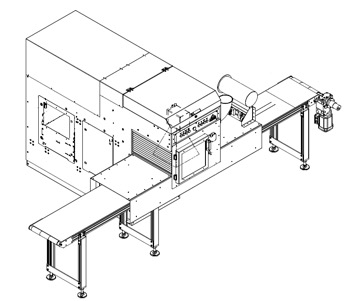

SlabCutter 15/200

The SlabCutter 15/200 is Zenna's innovative laser module for cutting plant-hole-patterns in substrate foil will offer you many advantages compared with the traditional substrate cutting systems. These systems ways of cutting holes and shapes into substrates is a very labor intensity process, which can be done much easier!

The Slabcutter 15/200 can cut any pattern in a slab that passes at a line speed of 60 m/min. It can handle slabs of maximum 200mm width and has no limitation in the length of the slabs. The minimum height for cutting the substrates slabs is 80 mm, and the maximum allowable height 120 mm.

The Slabcutter 15/200 module houses a 1.500 Watt CO2 laser and a scanner to manipulate the laser beam and create the shapes. The cutting compartment has an interlock door that guarantees the laser safety class 4 and also takes care of smoke removal.

Other benefits of the Slabcutter 15/200 are:

- All-on-one covered set-up

- Any pattern: circles, H-shapes, squeres, etc; fully loose or with mircro-joints

- Easy to design hole-patterns with pre-set shapes in the integrated library

- The powerful laser can cut any foil, seam and double folded

- Consistent cutting quality is ensured as there is no contact with the material

Cutting plant-hole-patterns in hydroculture slabs with a laser laser encounters a growing in popularity versus traditional cutting with a knife of heated mall. The use of a laser for cutting foil offers several advantages compared with the more traditional ways like: