PlateWeld Fiber

A fiber laser operates by using light energy to weld or cut materials. In the core of the laser, there is a special fiber, usually enriched with rare earth metals. This fiber is pumped with light pulses (diode lasers).

As these atoms return to their normal state, they emit light. This emitted light is coordinated into one powerful laser beam. This laser beam is then used to weld materials and create for example pillow plates.

What sets the fiber laser apart from the CO2 laser is the use of the fiber optic core to amplify the laser beam. This occurs through the process of stimulated emission of radiation. The amplified laser beam is then directed for welding with a long wavelength. Because the laser beam is compact and amplified, welding takes place in a closed compartment.

The ZennaLaser PlateWeld Fiber is Zenna's powerful welding system to produce pillow plates and dimple plates for the construction of isolated tanks and heat exchangers. The fiber laser allows to weld fast, producing up to 3 square meters pillow plate per hour. Also the weld depth and spot width are consistent and very well controlled, leaving the traditional TIG welding far behind in productivity. Especially in complex welding patterns, like cones or bottoms, the PlateWeld is an outstanding welding tool. The high level of process automation and the sophisticated PlateCam CAD software make the PlateWeld easy to operate and requires a minimum of staffing.

Other benefits of Zenna's PlateWeld Fiber are:

- Fiber lasers generally exhibit higher energy efficiency than CO2 lasers.

- Fiber lasers have a compact design and fewer moving parts compared to CO2 lasers

- Able to weld combi of 0.6mm on 2.5mm

- Water cooled clamping bars to prevent protection foil from melting

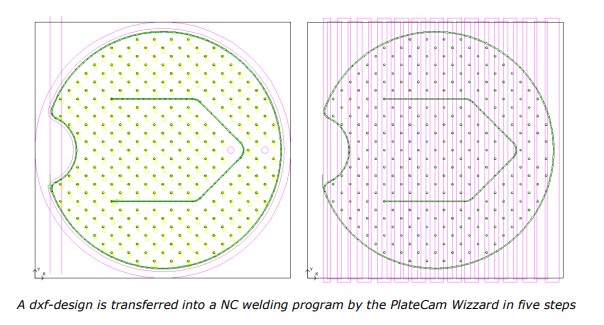

- Powerful PlateCam-CAD drawing software, with client specific design options

- Automatic Shrinkage Compensation to correct the welding pattern steps

- Decades of experience, resulting in maintenance and operator friendly design

- Offering preventive maintenance, breakdown support and spare parts supply

- Innovative options, e.g. Inline Weld Inspection

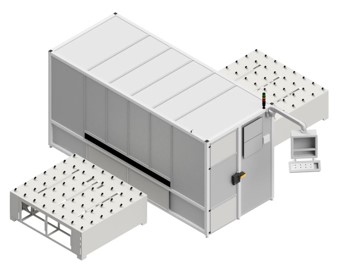

The PlateWeld Fiber system consists of two infeed- and two outfeed tables, a enclosed laser cabinet with a safety lock door and dome cameras to view the welding process. Two rigid clamping bars transport the plates in short indexing steps through the laser welding cabinet. Two other rigid clamping bars press the materials together during welding. Shielding gas is preventing oxidation of the top and bottom plate. The laser head creates the welding shapes, controlled by the welding program from the PlateCam - CAD Software.

ZocuPRO PlateCam software:

Zenna’s PlateCam II software is a very powerful, highly automated and user friendly software package. It helps the designer making complex shapes (e.g. bottoms) in a very efficient way. Many contours, like simple or double Dimple, Long holes and marking characters are stored in a library. Transport steps are automatically generated, but can also be edited and optimized to get a better welding position or increase efficiency. When using a double laser head PlateWeld, the software will propose load balancing to have both heads similar occupied.