Topics

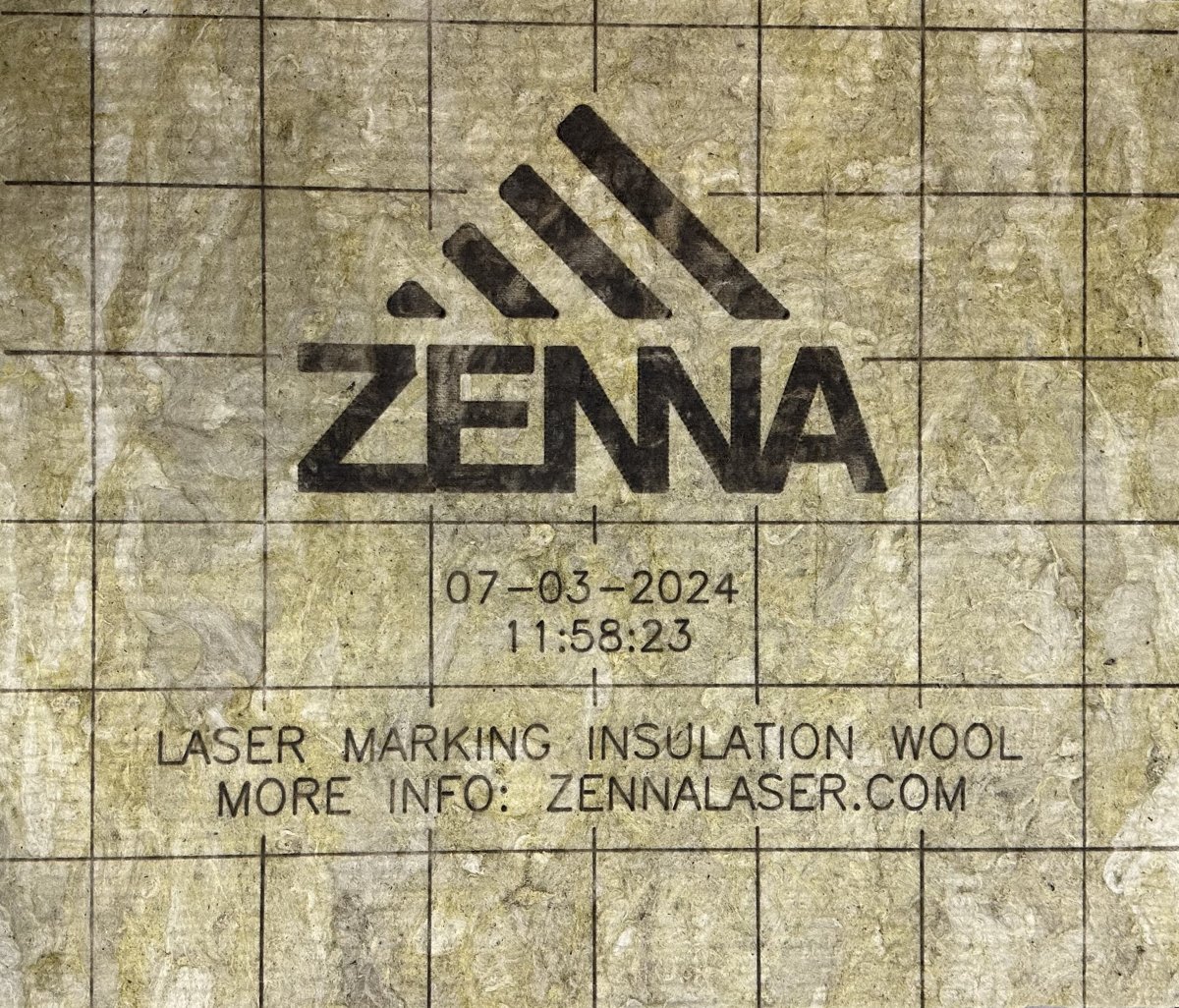

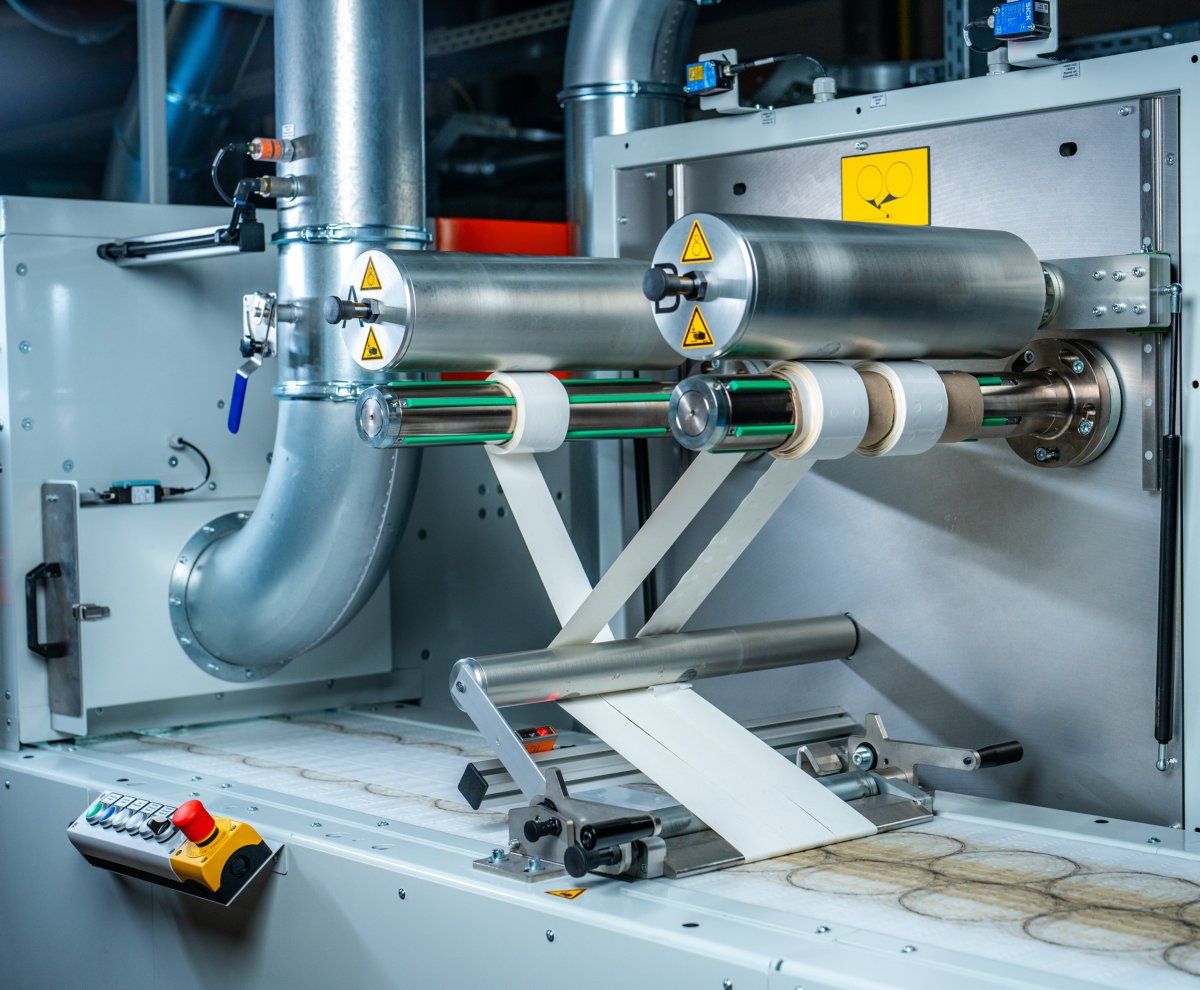

At Zenna, excellence and innovation are at the heart of everything we do. Our commitment is valued by customers and drives our success. We actively listen to customer needs and monitor supplier developments, but we often lead the way by introducing new technologies. Whether it is offering concept sketches or running pilot tests, we are confident these innovations improve our customers’ processes. While this approach involves some risk, our track record proves we deliver results. Read more about our innovations on our blogs: