Optimizing brand visibility in insulation manufacturing: Space-efficient solutions for Logo and RD-Value Marking

Have you ever felt the need to brand your insulation material with a logo or name? Do your clients often ask to mark the RD-Value on wool panels as prove for their contract controller? The wish to fulfill this requirements is there, but you are confronted with space limitations in the production lines and the feasibility for a significant investment?

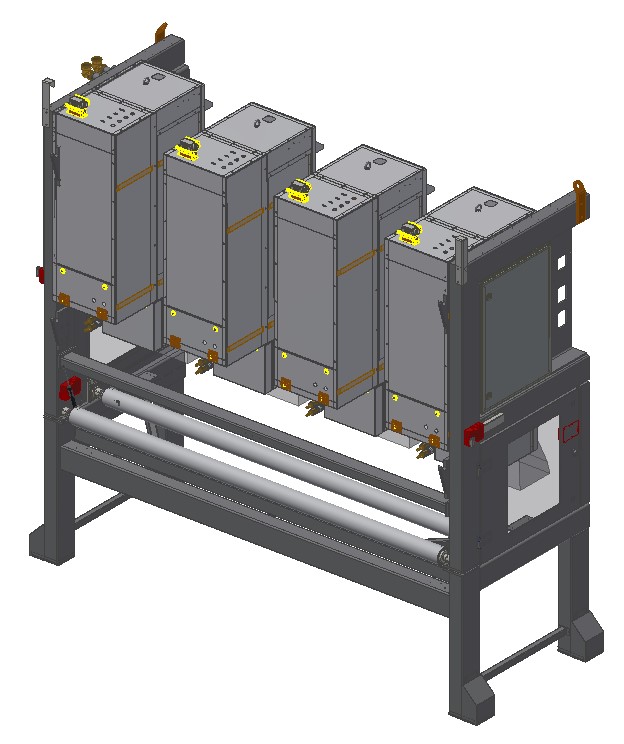

To address this need, Zenna introduces the MultiMarker Compact Module. This compact and scalable marking module is designed for seamless integration into existing production lines, occupying less than 2 meters in length between the cooling zone and the saws!

With the MultiMarker Compact, you can effortlessly switch between your desired marking patterns and Rd-value without halting your production line. Waiting for the costly gas-heated hot wheels to cool down is now a thing of the past!