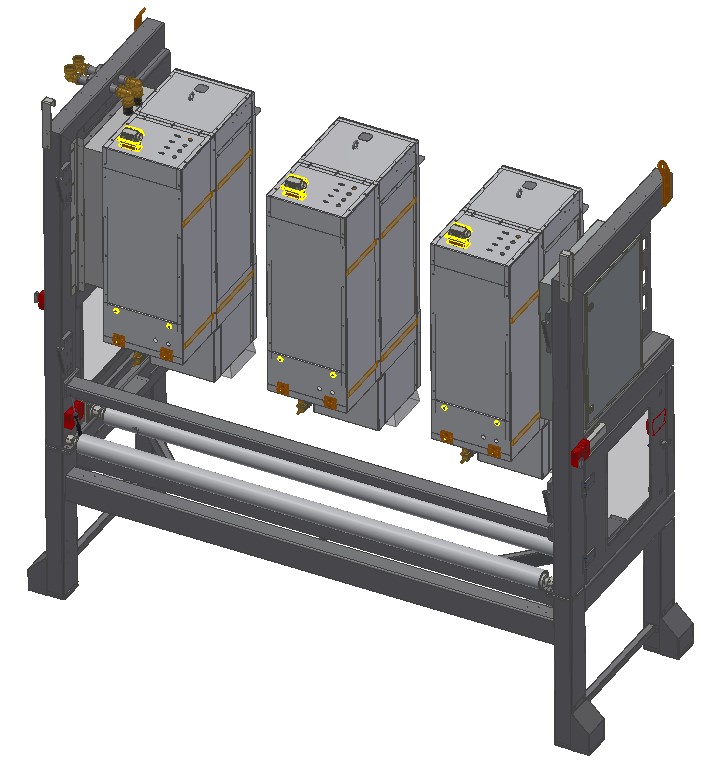

MultiMarker Compact

Have you ever wanted to brand your insulation materials with a logo or name? Do your clients often request the RD-Value to be marked on wool panels as proof for their contract inspectors? While the desire to meet these requirements exists, you encounter space limitations in your production lines and concerns about the feasibility of a significant investment.

Zenna addresses this need with the introduction of the MultiMarker Compact Module. This versatile and compact marking module is designed for easy integration into existing production lines, requiring less than 2 meters of space between the cooling zone and the saws!

With the MultiMarker Compact, you can seamlessly switch between different marking patterns and RD-Value indications without interrupting your production line. The hassle of waiting for expensive gas-heated hot wheels to cool down is now a thing of the past!

The conventional method for marking insulation material typically involves a traditional hot wheel. This wheel, which features a specific pattern, burns the design onto the material using a costly gas-heated system. When a pattern change is required, the wheel must cool down, and new patterns must be installed, leading to a temporary halt in production. This downtime consumes valuable time that could be better spent on maintaining efficient and uninterrupted production and marking.