Protection Window Contamination Sensors: Preventive Intelligence for Laser Cutting Systems

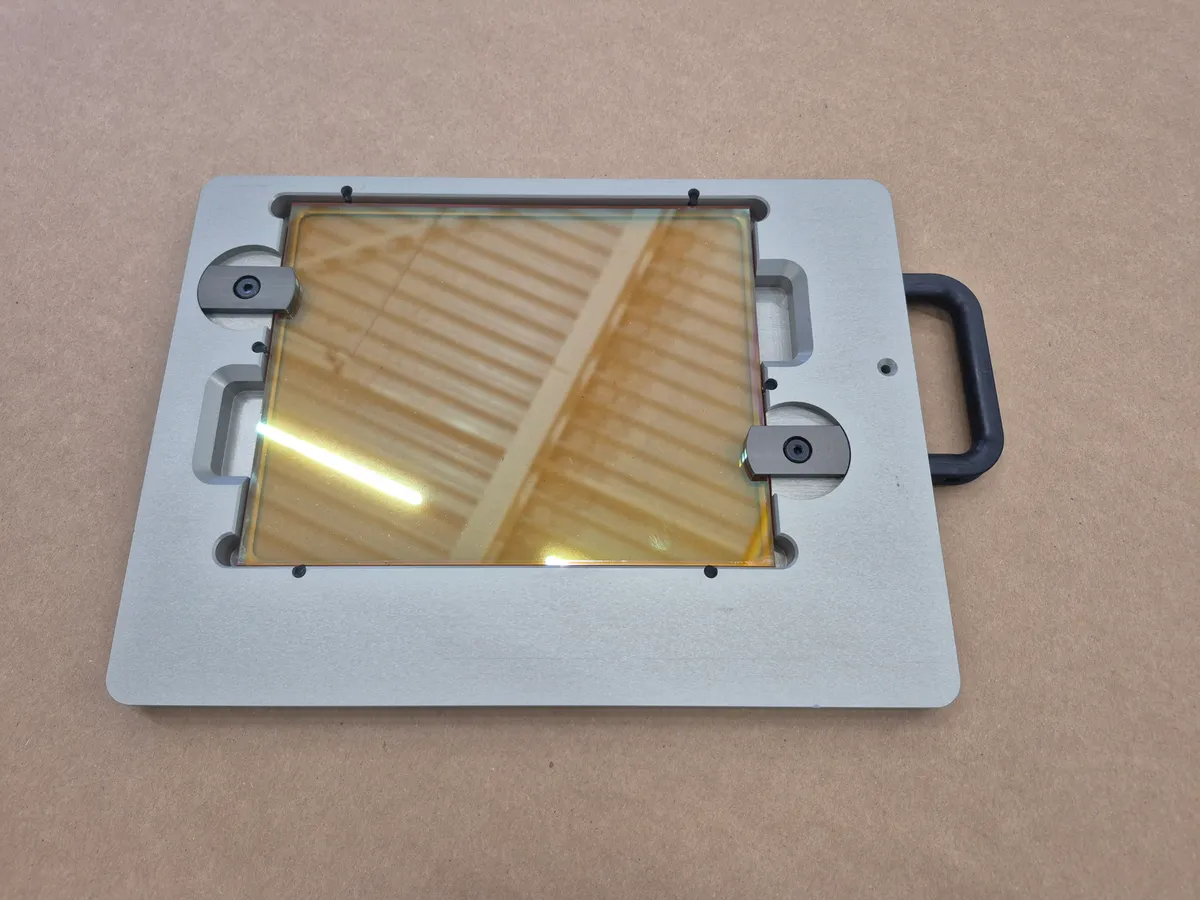

In high-performance laser systems, the protection window (PW) is a critical component. It shields the optical system from smoke, dust, and debris generated during laser processing, But ironically, it is also the first to suffer from contamination.

Over time, smoke and dust particles can settle on the PW surface. If not cleaned in time, this contamination burns into the glass under high laser intensity, degrading transmission and beam quality. Cleaning too often, however, causes unnecessary wear of the coating and limits the life time of the protection window.

Zenna's Innovation: Real-Time PW Contamination Monitoring

To solve this, Zenna developed an intelligent sensor system that continuously monitors the condition of the protection window during laser operation. This technology tracks optical changes caused by smoke buildup and reacts automatically when contamination levels become critical.

How it works:

- A built-in optical sensor monitors the beam transmission or scattered light levels through the PW.

- The system recognizes early signs of smoke-related contamination, based on changes in intensity, beam profile, or signal-to-noise ratio.

- Once the contamination exceeds a pre-set threshold:

- The operator is alerted via software interface Optionally, the system automatically pauses or shuts down the laser to prevent damage

- Data logging allows for trend analysis and smarter maintenance planning.

Benefits at a glance

Extended lifetime of protection windows

Only clean when truly needed - prevent unnecessary handling and extend component life.

Improved process reliability

Avoid power loss or beam distortion due to unnoticed contamination.

Damage prevention

Stop the laser automatically before contamination causes irreversible damage to optics.

Data-driven maintenance

Track contamination trends for specific materials or process conditions - optimize your maintenance schedule.

For Whom?

This solution is ideal for:

- High-duty laser systems in intense production environments

- Industrial manufacturers using lasers in critical processes

- Companies processing dusty, resin-heavy or smoke-intensive materials (e.g. insulation, textiles, abrasives or foams)

- Quality-driven industries like aerospace, automotive, electronics and building materials

Zenna’s contamination sensor system is available as an integrated option on our laser cutting and marking modules or as a retrofit kit for existing Zenna installations. Contact our team to discuss compatibility and implementation in your setup.