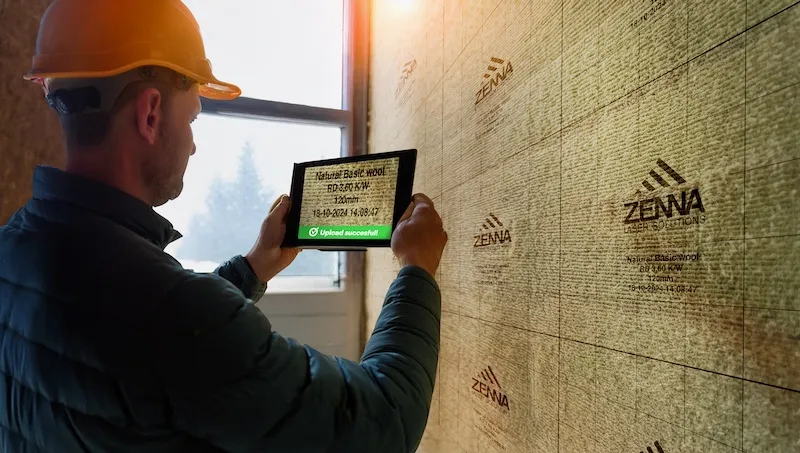

Grit marking on Insulation Wool: Technical precision with major on-site benefits

On construction sites, speed and precision are key. Every mistake in sizing or adjusting dimensions of materials cost time and money. That’s why manufacturers of insulation wool are under pressure to deliver products that support fast and accurate installation on the job site. Grit marking on insulation wool, applied with industrial laser systems, is emerging as a smart solution to meet these demands.

Advantages for the end user on-site

1. Faster installation

Pre-marked cutting guides mean installers don’t need to measure or mark manually, they can simply cut and place.

2. Fewer mistakes, less waste

Accurate markings reduce cutting errors and material waste, improving productivity and sustainability.

3. Better fit and airtightness

Properly aligned insulation improves energy efficiency and ensures compliance with increasingly strict building codes.

4. Improved safety

Clear markings reduce guesswork, especially when working at height or in confined spaces improving safety on the job.

Why choose laser-based marking?

Unlike mechanical methods like printing or embossing, laser marking offers maximum flexibility and minimal maintenance. No consumables are required, the marks are permanent and wear-resistant, and the system integrates easily with existing automation.

Commercial value for insulation manufacturers

By adding grit marking to your production process, you:

- Add real user value to your product without altering its core composition

- Increase your competitive edge by offering a more installer-friendly solution

- Differentiate your brand in a crowded market where small innovations make a big impact

Interested in a demo or pilot setup?

We provide custom laser solutions for insulation producers worldwide, with decades of experience and installations in Germany, the USA, and many other countries. Contact us today to discover how grit marking can enhance both your production process and your product’s value on site.