Laser cutting abrasives materials

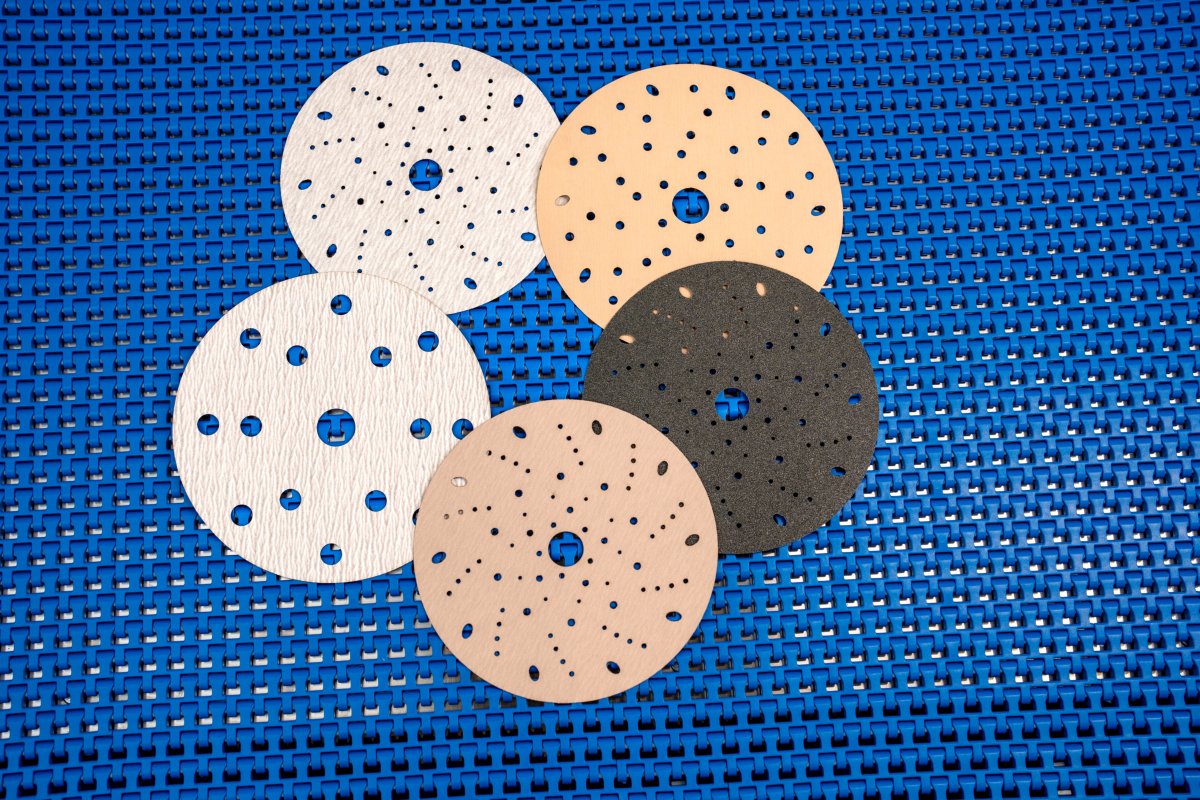

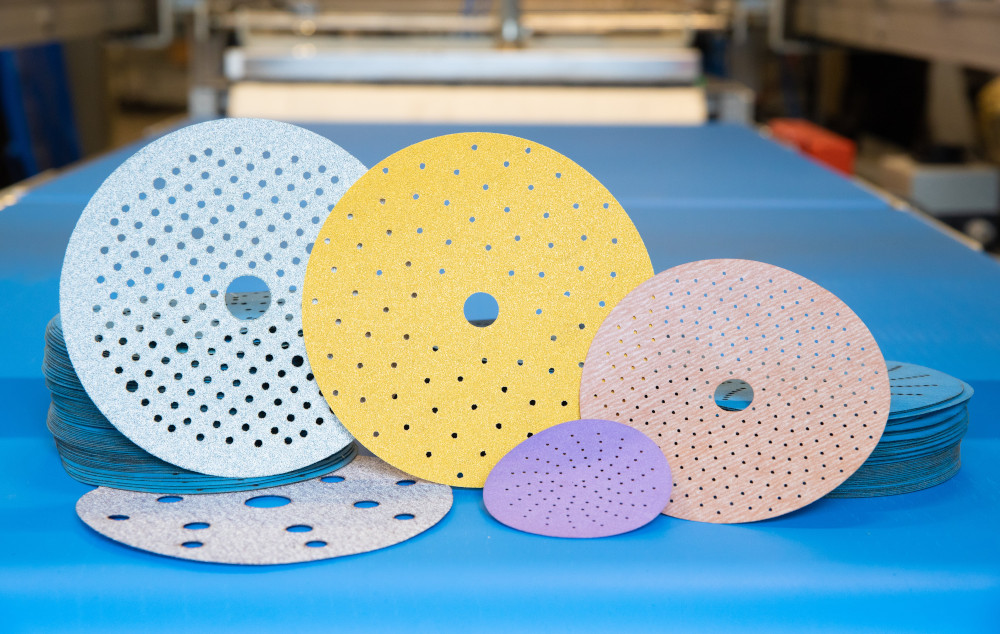

For a long time abrasives converting is dominated by knife slitters and die punchers. Two decades ago, Zenna launched a laser converting line, specially designed for cutting fiber discs, a difficult material for die-cutting. A decade later Zenna introduced the first wide web sandpaper converting line, designed to cut high volumes "multi-hole" discs and sheets. These high-end products differ from standard abrasives shapes in added value. Cutting 100, 200 or even 350 small holes for improved dust extraction has become the standard in the car repair market. But even for generic abrasive materials and shapes, laser cutting offers significant advantages versus die and knife:

- Less waste, as the laser can cut (nearly) disc-to-disc

- Eliminates wear on tooling, saving cost of sharpening

- High quality and precision of the edge in any shape thinkable

- From first to last part a constant quality, contact-free cutting

- Only seconds changeover time between different jobs

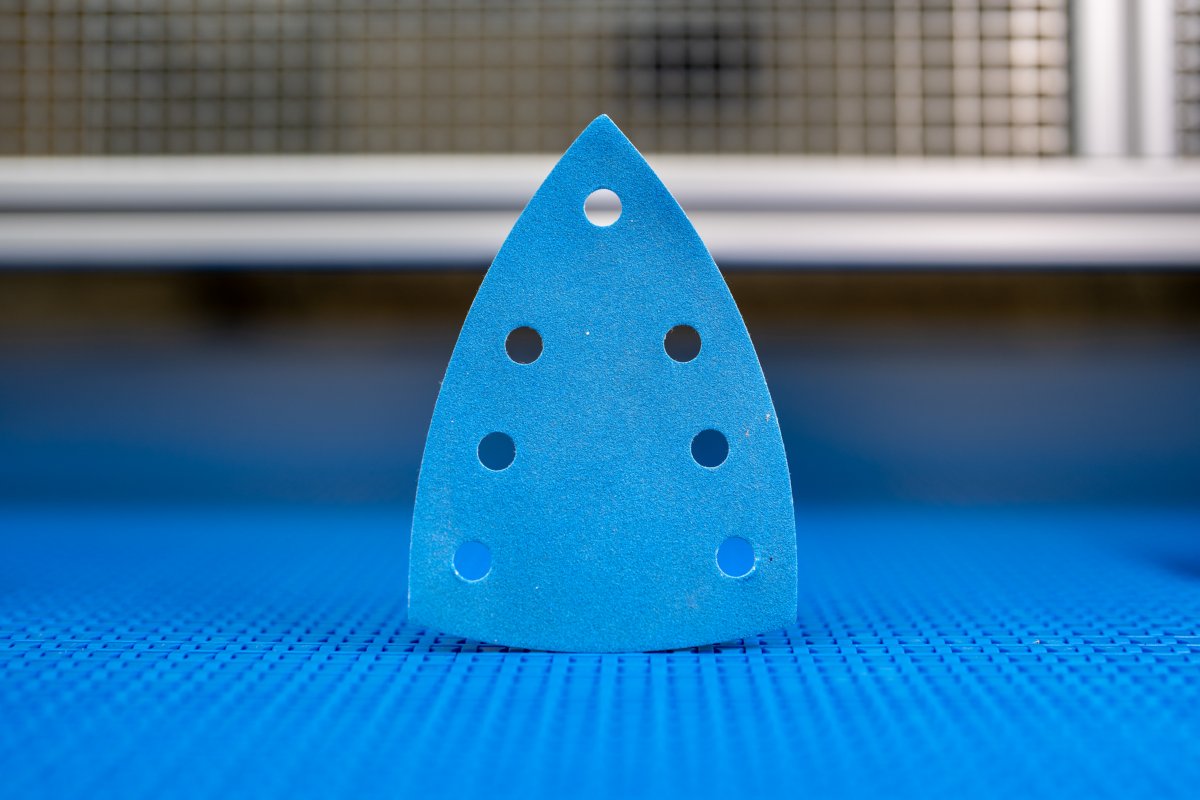

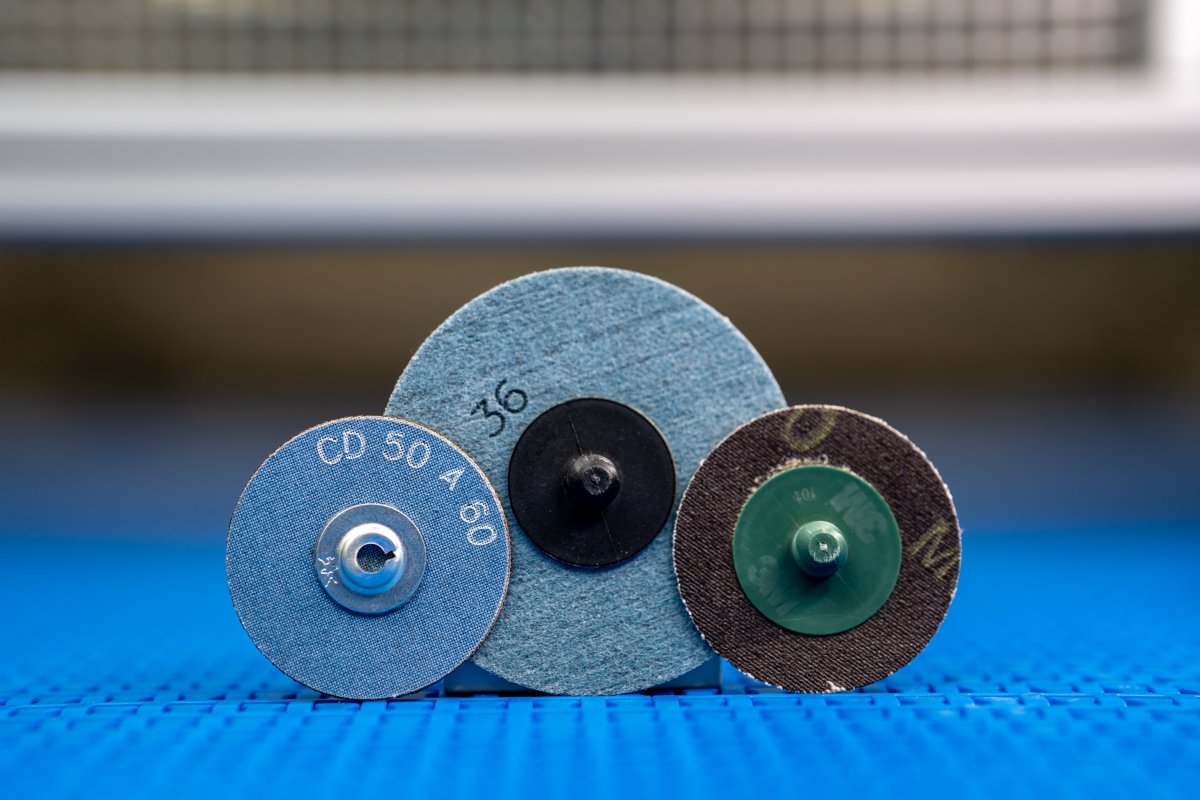

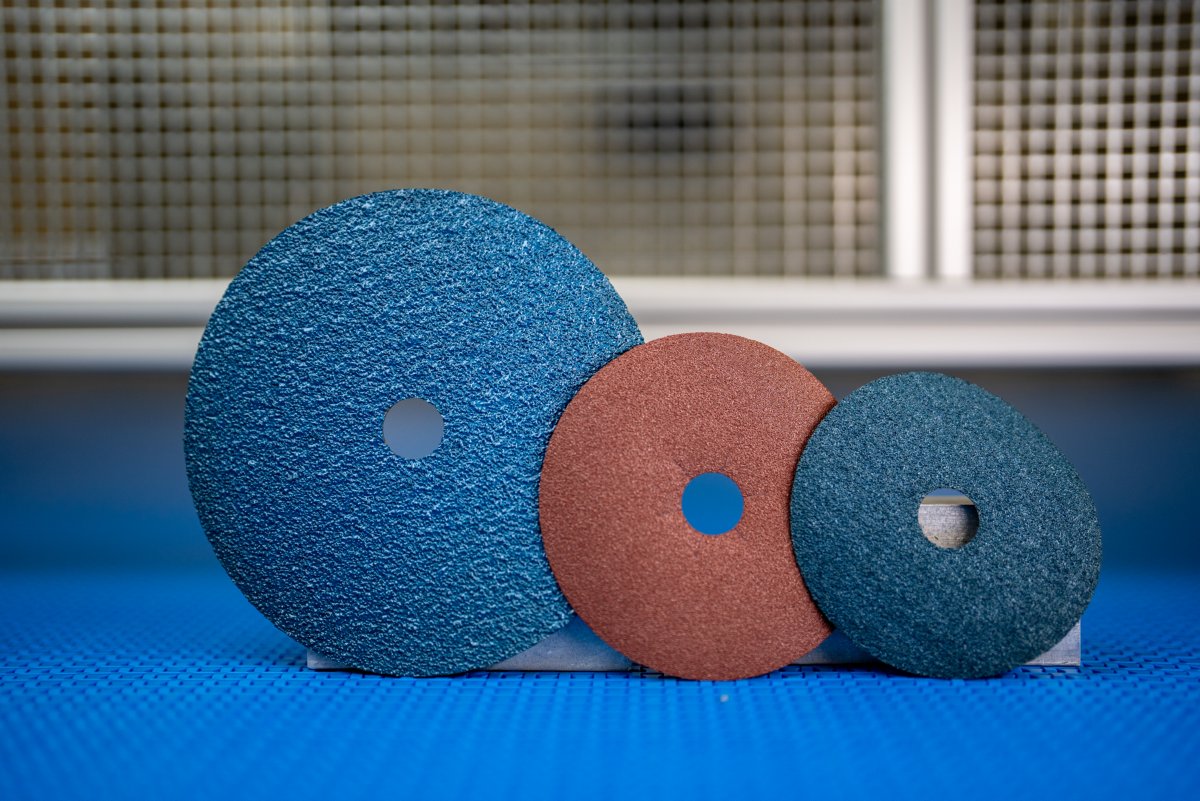

Zenna offers a wide range of abrasive cutting systems, either specialized for a specific material like fiber and heavy cloth or more generic materials, like Velcro, paper, film and PSA. Each of these materials can range from P24 to P1000, which is no problem for laser cutting. There are laser cutting systems for narrow web up to 500 mm (FlexCutter) and half to full web of 750 mm up to 1700 mm (MultiCutter).

The major reasons to consider laser cutting systems of Zenna are:

Flexibility

- Any shape - disc, belt, sheet, brush, button disc, flower,

- Any hole size & pattern – multi-hole, 1 mm ~ 10 mm holes, slits, fingers,

High productivity (OEE)

- No change-over time

Design possibilities

- Special shapes, multi-holes, waves, sharp edges

Low maintenance

- Hardly any moving parts

- Minor weekly, monthly inspection, Zenna Service Contract for preventive maintenance

Consistent quality

- First disc has same quality cut as the last disc of a job, no wear

- Sharp edges, no threats, no burning marks (with the exception of phenol-based raisin)