Introduction

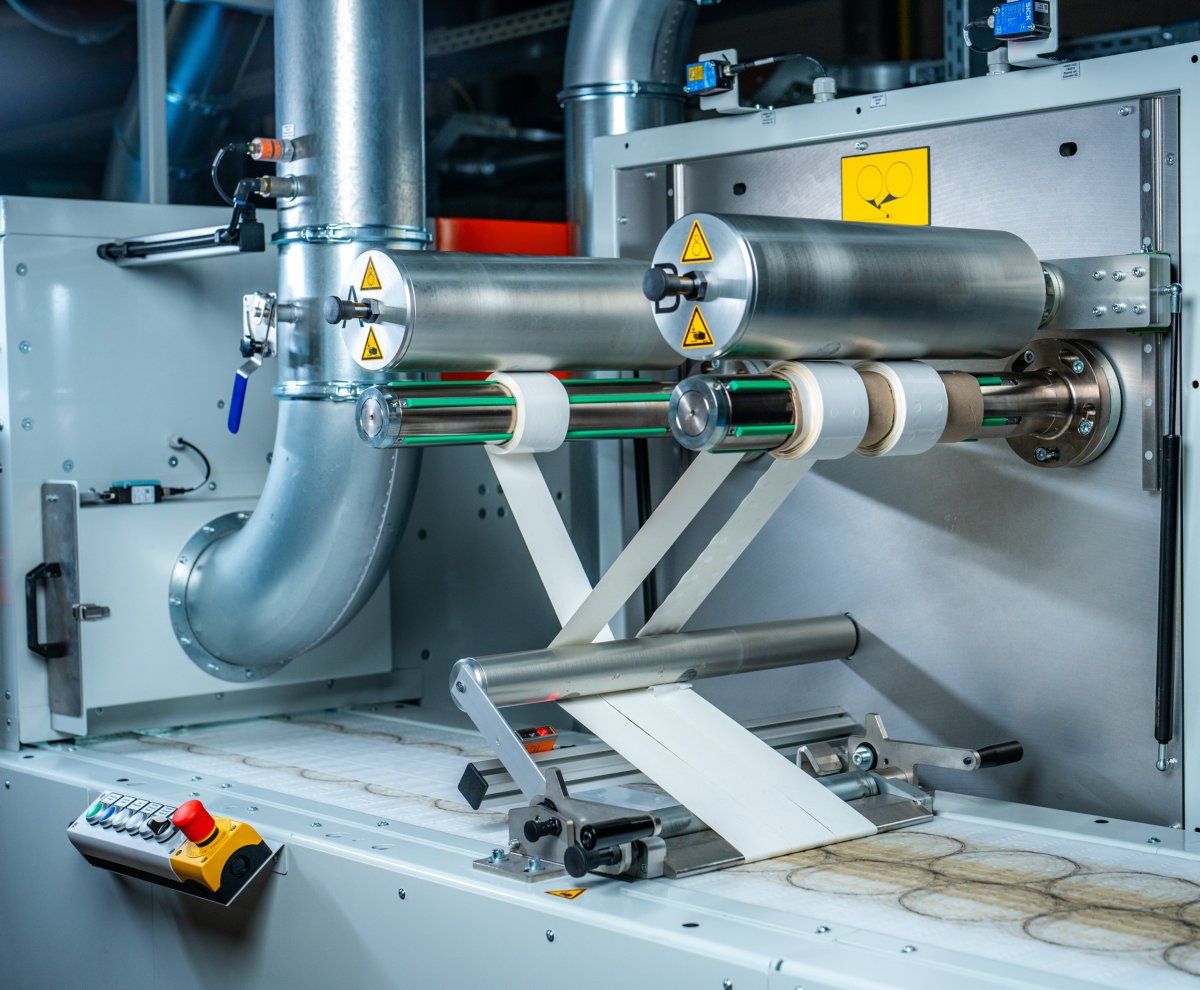

Zenna Laser Solutions designs and builds innovative industrial laser machines for laser cutting, laser welding, and laser marking purposes.

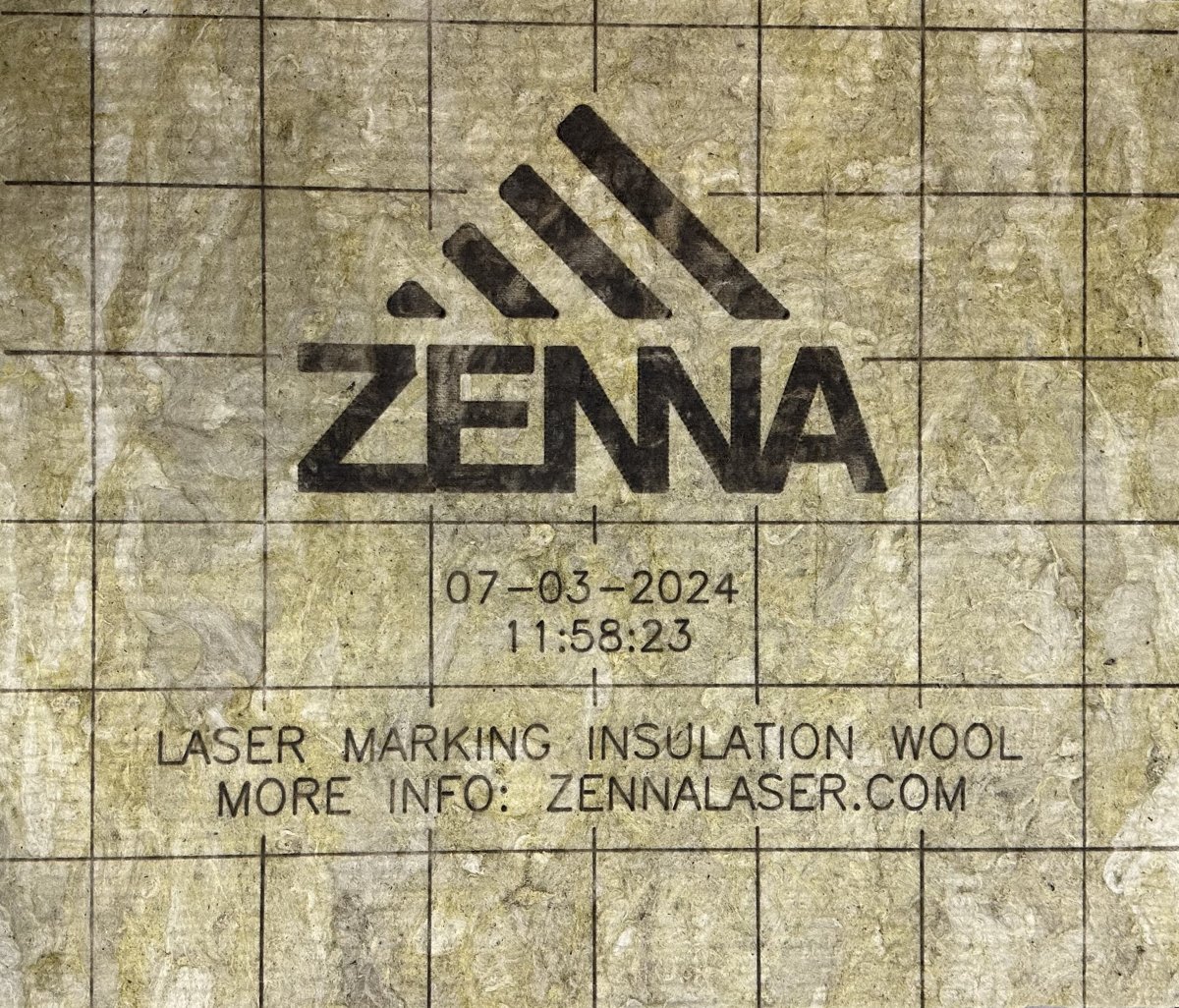

For over three decades, Zenna has engineered and manufactured client-specific laser systems for customers worldwide in various industries, including cutting abrasives, cutting airbags, welding isolating pillow plates and marking insulation wool. We also engineer and produce special applications laser machines for highly accurate cutting of (optical) film and thin metal foil.

Our success drivers are to enhance capacity and to improve productivity and product quality for our customers, combined with a strong commitment to deliver what we promise. To achieve these goals we create innovate solutions with new and proven technologies and an increasing level of automation.

"Together we innovate your production."